贵州航天风华精密设备有限公司

贵州航天风华精密设备有限公司2024届秋季招聘公告

贵州航天风华精密设备有限公司,简称航天风华,是隶属中国航天科工集团第十研究院的航天产品总装公司,国家高新技术企业和全国文明单位。 公司位于贵州省贵阳市经济技术开 简介:贵州航天风华精密设备有限公司成立于,是中国航天科工旗下企业,位于贵州省贵阳市花溪区,法定代表人为吴以华,目前处于存续(在营、开业、在册)状态, 贵州航天风华精密设备有限公司 企查查4 天之前 贵州航天风华精密设备有限公司是一家以专用设备制造业为主的企业,成立于2005年,位于贵州省贵阳市,拥有强大的机电产品设计制造能力和高性能铝镁合金精密成型技术。公司参与了国家重点工程三大加速器 贵州航天风华精密设备有限公司 搜狗百科贵州航天风华精密设备有限公司,成立于,位于贵州省贵阳市,是一家以从事铁路、船舶、航空航天和其他运输设备制造业为主的企业。 企业目前的经营状态为存续,注 贵州航天风华精密设备有限公司 企知道

贵州航天风华精密设备有限公司2025届秋招宣讲会应届

4 天之前 贵州航天风华精密设备有限公司 (中国航天0611研究所) 招聘简章 贵州航天风华精密设备有限公司(中国航天0611研究所),是中国航天科工集团第十研究院所属航天 简介: 贵州航天风华精密设备有限公司成立于,法定代表人为吴以华,注册资本为14564 万人民币,统一社会信用代码为,当前处于存续状态。贵州航天风华精密设备有限公司 启信宝贵州航天风华精密设备有限公司成立于2005年12月06日,注册地位于贵州省贵阳市经济技术开发区,法定代表人为吴以华。 经营范围包括法律、法规、国务院决定规定禁止的不得 贵州航天风华精密设备有限公司 爱企查CNA CN93A CN9A CNA CN A CN A CN A CN 9 A CN9 A CN 9A CN A CN A CN A Authority CN China Prior art keywords parts die epoxy resin resin agent Prior art date Legal CNA 一种树脂模具及其制作方法 Google Patents

.jpg)

CNU Mr线圈的低压浇注系统 Google Patents

CNU CN04U CN0U CNU CN U CN U CN U CN 0 U CN0 U CN 0U CN U CN U CN U Authority CN China Prior art keywords coil die cavity hole ingate cross gate Prior art date Legal CNA CN8XA CN8A CNA CN A CN A CN A CN 8 A CN8 A CN 8A CN A CN A CN A Authority CN China Prior art keywords module test test case script flow diagram Prior art date CNA Google PatentsThe invention discloses an A357 aluminum alloy material containing alterant Sr and Ti The A357 aluminum alloy material is characterized by comprising the following raw materials in percentage by mass: 67 of Si, 0406 of Mg, less than 005 of Cu, 012 of Ti, 0010015 of Sr, 02 of Fe, and the balance of AlA357 aluminum alloy material containing alterant Sr and Ti and 본 발명은 BAF 소둔 공정에 있어서 가열시간과 온도, 가열유지시간과 온도 및 냉각시간과 온도를 인장강도 35kg/㎟ 이상의 고장력 자동차강판 용도의 요구 조건으로 각각 설정하여 열처리 하므로써 용도에 충족할 수 있는 기계적 특성치를 얻을 수 있는 최적 BAF 소둔 열처리 방법에 관한 것이다고장력 자동차강판의 상자소둔 열처리 방법 Google Patents

.jpg)

마그네슘합금 소성 가공품 및 그 제조방법 Google Patents

단조성을 확보하고, 크랙이나 표면의 흑변, 연소를 억제하는 소성 가공품의 제조, 다이캐스팅 주조의 복잡형상의 성형성, 단조품의 고신뢰성, 고강도성을 동시에 실현시키고, 저렴하고 고품질의 소성 가공품의 제조, 및 필요에 따라서 마그네슘합금 판재를 저렴하게 제조할 수 The present invention provides a kind of detection method of yttrium in nickelbase alloy, comprising the following steps: (1) prepares sample solution;(2) matrix blank solution is prepared;(3) standard working solution is prepared;(4) standard curve is drawn;(5) optimized analysis spectral line is selected;(6) matrix blank solution is detected;(7) The detection method of yttrium in a kind of nickelbase alloyA pouring system and composite technology, applied in the field of casting systems, can solve the problems of difficult pouring, shrinkage, and difficult to achieve feeding, and achieve the effect of ensuring onetime molding, good Composite casting system Eureka Patsnap본 고안은 자주포나 곡사포의 사격시 추진장약의 연소에 의한 추진 가스를 밀폐 시켜주는 뇌관 밀폐링을 직접 사격을 행하지 않고 동일조건에서 내구도시험을 이룰 수 있도록 하는 것으로 종래에는 뇌관밀폐링의 내고도 시험장치가 구비되자 않아 곡사포의 뇌관 밀폐링 내구도 시험장치 Google Patents

.jpg)

Process for smelting magnesium alloy Google Patents

The invention discloses a process for smelting magnesium alloy The process comprises the following steps of: heating and smelting magnesium alloy flux containing MgCl2; adding a preheated crudemagnesiumcontaining magnesium alloy charging material in batches; and removing residual magnesium alloy flux after all the charging material is A CN00A CN0A CNA CN A CN A CN A CN 0 A CN0 A CN 0A CN A CN A CN A Authority CN China Prior art keywords temperature phase lpso heat treatment magnesium Prior art date CNA 稀土镁合金的热处理工艺 Google PatentsUSA1 US17/914,728 US8A USA1 US A1 US A1 US A1 US 8 A US8 A US 8A US A1 US A1 US A1 Authority US United States Prior art keywords fire ignition device fighting explosive charge casing Prior USA1 Firefighting device Google PatentsCNA CN95A CN9A CNA CN A CN A CN A CN 9 A CN9 A CN 9A CN A CN A CN A Authority CN China Prior art keywords full insulating frequency wave temperature heat coating Prior art date CNA Google Patents

一种复合材料机翼整体成型工艺方法及工装 Google Patents

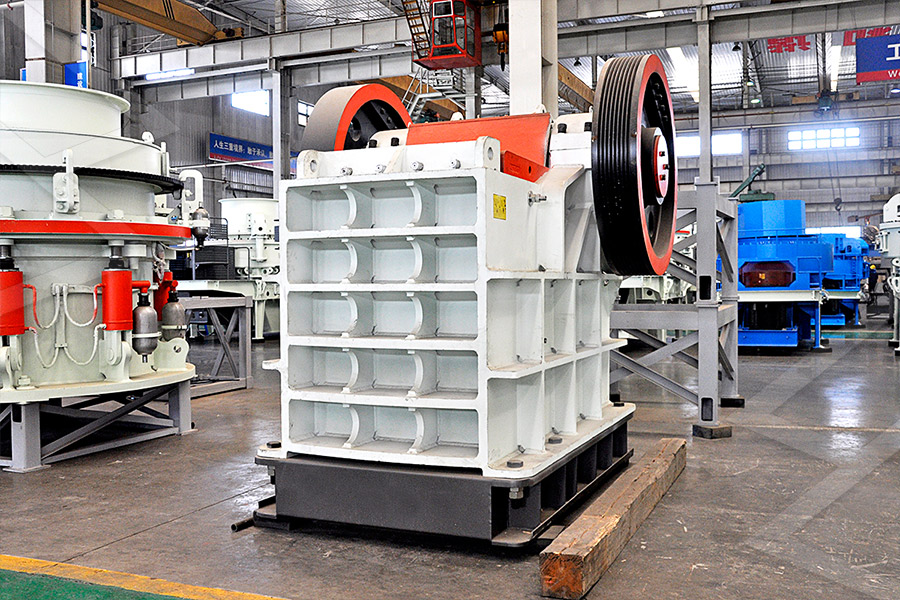

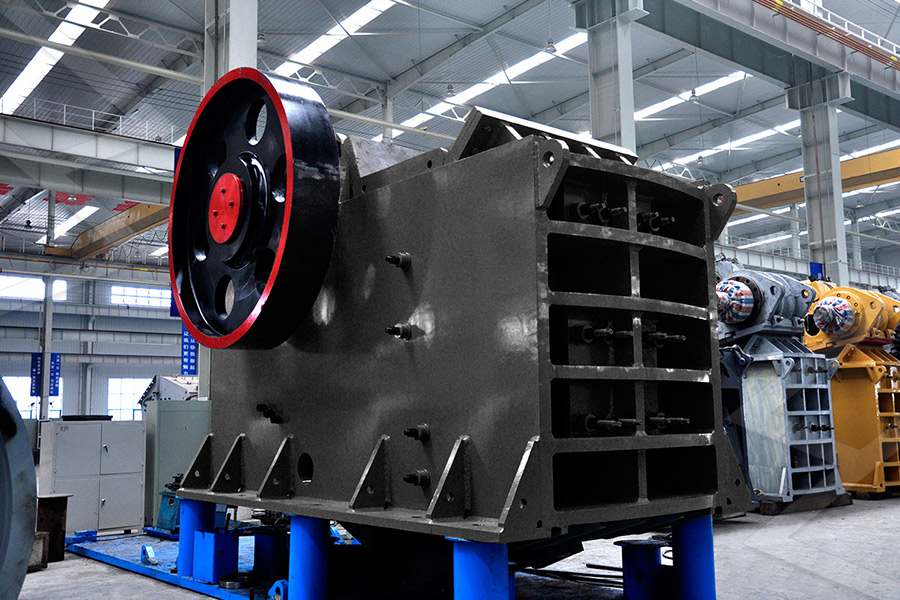

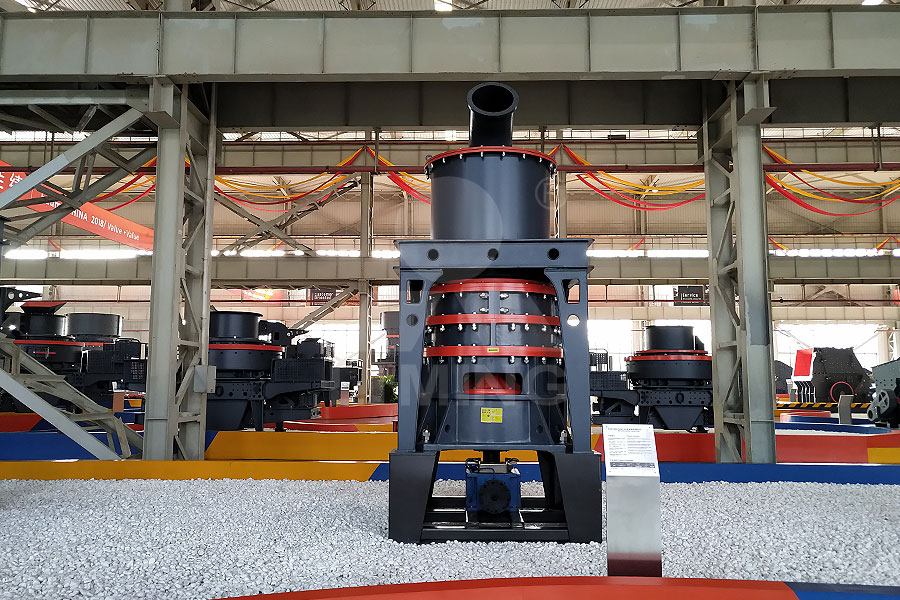

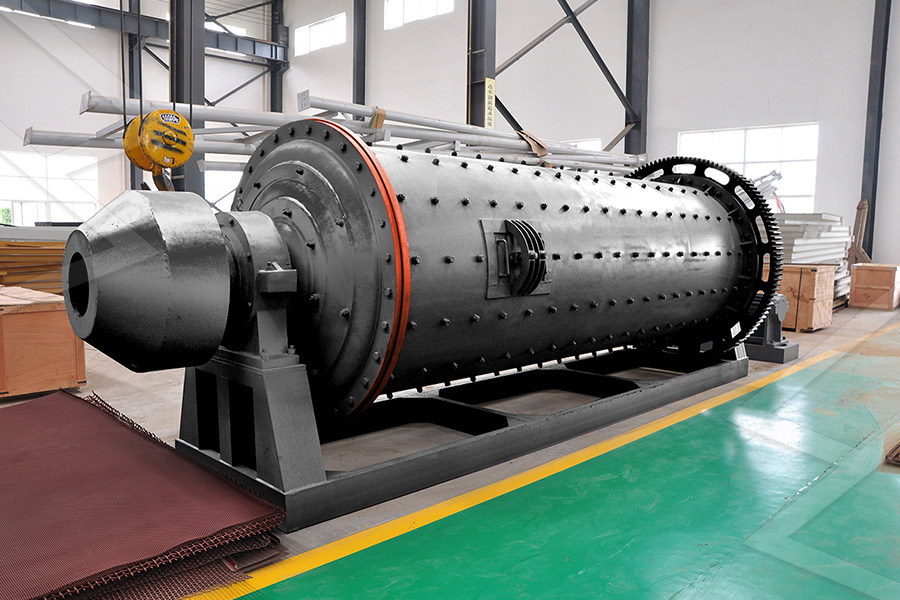

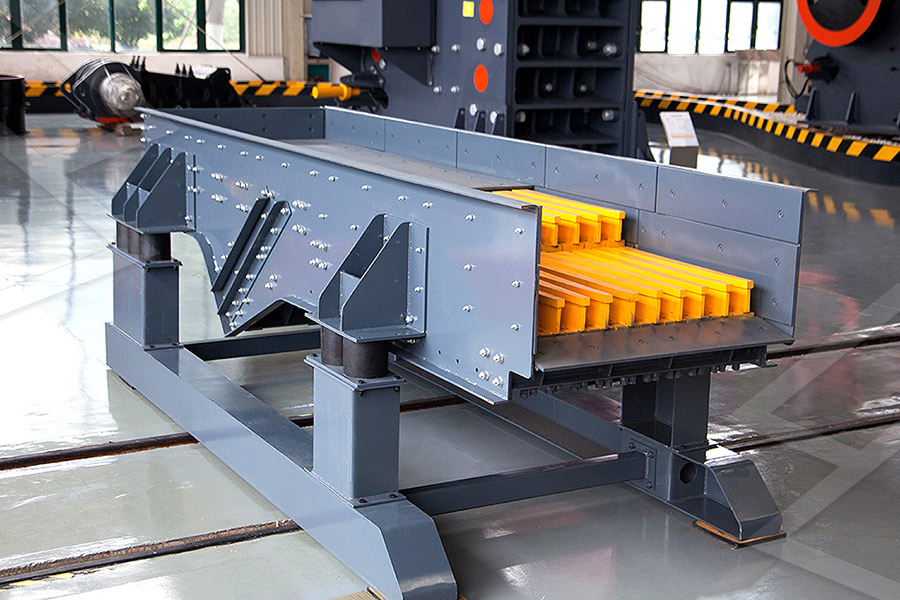

CNA CN79A CN7A CNA CN A CN A CN A CN 7 A CN7 A CN 7A CN A CN A CN A Authority CN China Prior art keywords former wing composite material formpiston counterdie Prior art date Products AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant贵州 钢材破碎 设备 制造EPA4 EP5A EPA EPA4 EP A4 EP A4 EP A4 EP A EP A EP A EP A4 EP A4 EP A4 Authority EP European Patent Office Prior art keywords iron aluminum zirconium alloys zirconium alloys Prior art date Legal status (The EPA4 Aluminumironzirconium alloys Google Patents본 발명은 노즐 헤드를 x, y, z의 3개의 축을 중심으로 선형 이동 가능하게 함과 더불어 3개의 축을 중심으로 회전 운동 가능하게 구성하여 원하는 입체 형상을 정확하게 구현할 수 있는 6자유도 3차원 프린터에 관한 것으로, 본 발명에 따른 KRB1 6자유도 3차원 프린터 Google Patents

.jpg)

Torsion spring powered missile wing deployment system

A foldable missile wing is deployed by means of an overcenter linkage powered by a torsion spring assembly capable of exerting a generally linear bias on the linkage over its full range of motion A separate lock linkage maintains the foldable wing in a deployed position until release actuation of the lock linkage occurs thereby enabling wing B CN30A CN3A CNB CN B CN B CN B CN 3 A CN3 A CN 3A CN B CN B CN B Authority CN China Prior art keywords axis print platform color lump spray head sliding block Prior art date CNB 三轴并联式3d打印机及其校正方法 Google The invention discloses a method for machining a thinwall aluminum alloy part The method comprises the following steps of: selecting cutters, positioning, performing rough machining, performing semi finish machining, performing ageing treatment, performing standard finish machining, and performing finish machining By the method, the dimension of the part Method for machining thinwall aluminum alloy partChinese patent literature discloses a kind of big gun, and (notification number: CNY), it is made up of the body of the magnetic tape trailer wing and nosefuze and the launch point firearm that is assembled on the body, and extinguishing chemical and scattering mechanism are housed in the body with fire extinguisher bombIts full bullet Mortar bomb for extinguishing forest fire Google Patents

CNA 一种筒形铸件缺陷控制系统 Google Patents

CNA CN38A CN3A CNA CN A CN A CN A CN 3 A CN3 A CN 3A CN A CN A CN A Authority CN China Prior art keywords casting control system star pouring annular Prior art date CNA CN27A CN2A CNA CN A CN A CN A CN 2 A CN2 A CN 2A CN A CN A CN A Authority CN China Prior art keywords silver temperature plating layer time washing Prior art date 201612 CNA Google PatentsThe invention belongs to the field of firefighting equipment, and provides a fire extinguishing bullet firing device launching under a low chamber pressure to realize reliable firing of a firing device by releasing mechanical lock under the low chamber pressure The fire extinguishing bullet firing device comprises a tail piece, a push plate, a base, a connecting piece, a CNA Mechanical fire extinguishing bullet firing device JPA JPA JPA JPA JP A JP A JP A JP A JP A JP A JP A JP A JP A JP A JP A JP A Authority JP Japan Prior art keywords piston silicon alloy aluminum JPA 改善されたアルミニウムシリコン合金

USA Extended canister flythrough cover Google Patents

a conventional design canister cover 50 would permit this compressed gas to reach far too great a pressure prior to the nose 52 of the weapon 44 punching through the cover 50 in the conventional manner as described above This pressure build up within canister 46 would tend to cause the cover 50 to bulge out More importantly, stress analysis has indicated CNA CN14A CN1A CNA CN A CN A CN A CN 1 A CN1 A CN 1A CN A CN A CN A Authority CN China Prior art keywords aluminum alloy alloy materials titanium dioxide parts processing Prior 一种提升铝合金材料耐腐特性的处理方法 Google Patents본 발명은 운동에너지 발사체에 대한 개선된 저항을 갖고, 10 mm 이상의 게이지를 갖는 알루미늄합금 플레이트에 있어서 알루미늄합금은 중량%로, 40 내지 60 Mg, 02 내지 14 Mn, 최대 09 Zn, Zr<03, Cr<03, Sc<05, Ti<03, Fe<05, Si<045, Ag<04, Cu<025, 기타 원소 및 불가피한 불순물은 각각 <005, 전체 KRA 장갑판재용 AlMg 합금 Google PatentsCNA CN 5 CN5A CNA CN A CN A CN A CN 5 CN5 CN 5 CN 5 A CN5 A CN 5A CN A CN A CN A Authority CN China Prior art keywords mold casting CNA Google Patents

.jpg)

CNA 镁合金板、其制造方法和成形体 Google Patents

CNA CN17A CN1A CNA CN A CN A CN A CN 17 A CN17 A CN 17A CN 1 A CN1 A CN 1A CN A CN A CN A Authority CN China Prior art keywords Process for economically obtaining a magnesium alloy having improved mechanical characteristics and in particular a breaking strength of at least 290 MPa and an elongation at break of at least 5%, by spraying and deposition in solid form to provide an ingot with the following weight composition: Al 29%; Zn 04%; Mn 01%; Ca 055%; RE 04% (rare Process for obtaining magnesium alloys by spray depositionJPA JPA JPA JPA JP A JP A JP A JP A JP A JP A JP A JP A JP A JP A JP A JP A Authority JP Japan Prior art keywords aluminum mass mass ppm ppm JPA アルミニウム処理方法 Google PatentsCNB CN62A CN6A CNB CN B CN B CN B CN 6 A CN6 A CN 6A CN B CN B CN B Authority CN China Prior art keywords magnesium flux cuttings application method magnesium alloy Prior art Flux used for recycling magnesium alloy cuttings, and preparation

CNA 一种湿垃圾负压收集处理系统 Google Patents

CNA CN71A CN7A CNA CN A CN A CN A CN 7 A CN7 A CN 7A CN A CN A CN A Authority CN China Prior art keywords negative pressure sewage pressure oil area wet garbage Prior art SELF DESTRUCTION IMPACT FUSE Field of the Invention [0001] The present invention generally relates to the technologies of ammunition detonation, and more particularly to a self destructing impact fuze that can detonate ammunition reliably when the ammunition is delivered by projectiles, especially the low velocity projectiles Background of the CAA1 Self destruction impact fuse Google PatentsCNC CNBA CNA CNC CN C CN C CN C CN B A CNB A CN BA CN A CN A CN A CN C CN C CN C Authority CN China Prior art keywords mold scope metal mold casting metal Prior art date CNC Google PatentsCNA CN21A CN2A CNA CN A CN A CN A CN 2 A CN2 A CN 2A CN A CN A CN A Authority CN China Prior art keywords paillon foil foil sealing spring rotating member Prior art date 200706 CNA 用于回转机械的密封组件 Google Patents

.jpg)

DE8A1 Verfahren zur Herstellung eines Google

Die Erfindung betrifft ein Verfahren zur Herstellung eines Kolbens einer Brennkraftmaschine, wobei ein Kolbenrohling aus einer AluminiumsiliziumLegierung unter Zugabe von Kupferanteilen gegossen und danach fertig bearbeitet wird, wobei erfindungsgemäß vorgesehen ist, dass der Kupferanteil maximal 5,5% der AluminiumsiliziumLegierung KRB1 KR36A KRA KRB1 KR B1 KR B1 KR B1 KR 36 A KR36 A KR 36A KR A KR A KR A KR B1 KR B1 KR B1 Authority KR South Korea Prior art KRB1 유도탄의 날개 전개장치 Google PatentsA production process and technology for aluminum alloys, applied in the field of aluminum alloys, can solve the problems of inability to meet the processing and forming, surface quality and heat treatment, and restrictions on the use of highstrength aluminum alloy materials, and achieve the effect of good aging resistance and stabilityHighstrength aluminum alloy and manufacturing process thereofCNA CN93A CN9A CNA CN A CN A CN A CN 9 A CN9 A CN 9A CN A CN A CN A Authority CN China Prior art keywords parts die epoxy resin resin agent Prior art date Legal CNA 一种树脂模具及其制作方法 Google Patents

CNU Mr线圈的低压浇注系统 Google Patents

CNU CN04U CN0U CNU CN U CN U CN U CN 0 U CN0 U CN 0U CN U CN U CN U Authority CN China Prior art keywords coil die cavity hole ingate cross gate Prior art date Legal CNA CN8XA CN8A CNA CN A CN A CN A CN 8 A CN8 A CN 8A CN A CN A CN A Authority CN China Prior art keywords module test test case script flow diagram Prior art date CNA Google PatentsA kind of containing alterant Sr, the preparation method of the A357 aluminum alloy materials of Ti, the prefabricated ingot of heat fused A357 alloy, during grain refining process, Al5%Ti master alloy is added after alloy pig heat fused, refining degasification when being warming up to 740 degree, cast after leaving standstill, during A357 aluminum alloy material containing alterant Sr and Ti and 본 발명은 BAF 소둔 공정에 있어서 가열시간과 온도, 가열유지시간과 온도 및 냉각시간과 온도를 인장강도 35kg/㎟ 이상의 고장력 자동차강판 용도의 요구 조건으로 각각 설정하여 열처리 하므로써 용도에 충족할 수 있는 기계적 특성치를 얻을 수 있는 최적 BAF 소둔 열처리 방법에 관한 것이다고장력 자동차강판의 상자소둔 열처리 방법 Google Patents

.jpg)

마그네슘합금 소성 가공품 및 그 제조방법 Google Patents

본 발명은 마그네슘합금 소성 가공품, 그 제조방법, 마그네슘합금 압출재 및 그 제조방법에 관한 것으로, 더욱 구체적으로, 본 발명은 (i) 소성 가공에 있어서 소성 가공성을 확보하고, 크랙이나 표면의 흑변, 연소를 억제하고, 소성 가공품의 기계적 강도를 확보하는 소성 The present invention provides a kind of detection method of yttrium in nickelbase alloy, comprising the following steps: (1) prepares sample solution;(2) matrix blank solution is prepared;(3) standard working solution is prepared;(4) standard curve is drawn;(5) optimized analysis spectral line is selected;(6) matrix blank solution is detected;(7) The detection method of yttrium in a kind of nickelbase alloyA pouring system and composite technology, applied in the field of casting systems, can solve the problems of difficult pouring, shrinkage, and difficult to achieve feeding, and achieve the effect of ensuring onetime molding, good Composite casting system Eureka Patsnap본 고안은 자주포나 곡사포의 사격시 추진장약의 연소에 의한 추진 가스를 밀폐 시켜주는 뇌관 밀폐링을 직접 사격을 행하지 않고 동일조건에서 내구도시험을 이룰 수 있도록 하는 것으로 종래에는 뇌관밀폐링의 내고도 시험장치가 구비되자 않아 곡사포의 뇌관 밀폐링 내구도 시험장치 Google Patents

.jpg)

Process for smelting magnesium alloy Google Patents

The invention discloses a process for smelting magnesium alloy The process comprises the following steps of: heating and smelting magnesium alloy flux containing MgCl2; adding a preheated crudemagnesiumcontaining magnesium alloy charging material in batches; and removing residual magnesium alloy flux after all the charging material is smelted