Crusher Chute Design Pdf 03 Miss Design Principles Chutes

MINIMIZING BELT WEAR AND DAMAGE FROM

2023年4月11日 An optimized curved chute design controls the flow of material, placing it onto the receiving belt where the material’s forward velocity approximates the belt’s 2007年2月12日 The paper describes how the relevant flow properties of bulk solids are measured and applied to chute design Chute flow patterns are described and the CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND This paper attempts to give the reader some simple rules to apply to chute design Any discussion on chute design would normally require at least a week of deliberations, Chute Design Essentials – How to Design and Implement 2016年2月24日 plug chutes, reduce surge capacity, and decrease the live storage capacity of bins and silos To address this problem, chutes must be easily accessible for cleanup, Crushing Plant Design and Layout Considerations 911

Conventional transFer Chutes fhubspotusercontent20

2021年1月14日 This chapter covers conventional transfer chute design Because each material and each application has its own characteristics, an effective transfer chute 2017年9月10日 This document discusses design principles for chutes used to direct the flow of bulk solids It outlines two key principles: 1) Chutes must be steep enough to prevent plugging at impact points like changes in Design Principles Chutes PDF Wear2021年7月8日 This document discusses two key design principles for chutes used to handle bulk solids: 1 Chutes must be steep enough to prevent material from adhering or plugging at impact points, such as StuartDickRoyalDesign Principles For Chutes 2024年6月6日 The design is obtained by a simulation based on the discrete element method (DEM), considering the mechanical properties of all the materials involved, with a Design of a Transfer Chute for Multiple Operating

Best Practice Design, Maintenance and Troubleshooting

2019年1月31日 7 Transfer Chutes 201 71 Introduction 201 72 Transfer Chute Theory 202 73 General transfer chute design considerations 211 74 Design principles for chutes Chutes are in use in almost every bulk solids handling plant Although everybody knows them, they are mostly overlooked, except for those cases where they cause extraattention and work due to malfunctioning Following you will find hints to prevent such incidents This paper attempts to give the reader some simple rules to apply to chute Chute Design Essentials – How to Design and Implement 2021年7月8日 This document discusses two key design principles for chutes used to handle bulk solids: 1 Chutes must be steep enough to prevent material from adhering or plugging at impact points, such as StuartDickRoyalDesign Principles For Chutes Transfer chutes are used in bulk handling systems to perform a variety of operations For instance accelerating the bulk material from a slow moving belt or apron feeder onto a conveyor, or capturing and redirecting the Transfer Chute Design TUNRA Bulk Solids

Transfer Chute Analysis with Discrete Element and

2020年4月1日 the chute design with DEM simulations then, as a minimum, a continuum model should be consulted to determine the chute’s minimum slope or cutoff angle The continuum model requires much less design work to be completed and can provide chute cutoff angles for several chute design options in a relatively short time2020年4月1日 Jenike Johanson Design principles for chutes to handle bulk solidspdf Free download as PDF File (pdf), Text File (txt) or read online for free Scribd is the world's largest social reading and publishing siteJenike Johanson Design Principles For Chutes To Handle 2016年2月24日 design, so that they can identify ways of reducing overall electrical power consumption • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001)Crushing Plant Design and Layout Considerations 911 4 天之前 The spiral chute combines the advantages of a spiral concentrator, shaking table, and centrifugal concentrator It is an essential tool for mineral processing and recycling It can effectively extract different minerals based on specific gravity The versatility and adaptability of spiral chutes make them suitable for various mineral processing Improving Mineral Processing Efficiency With Spiral Chutes

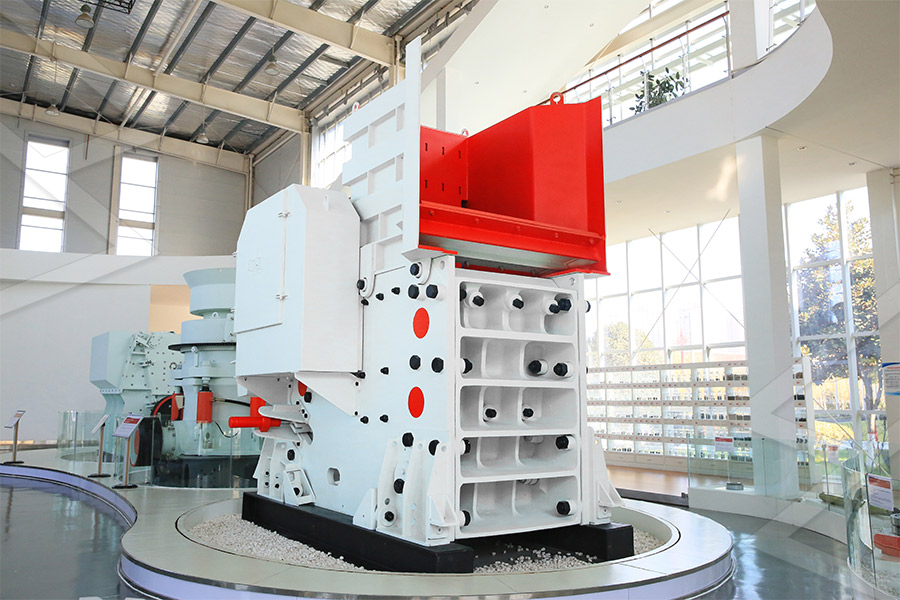

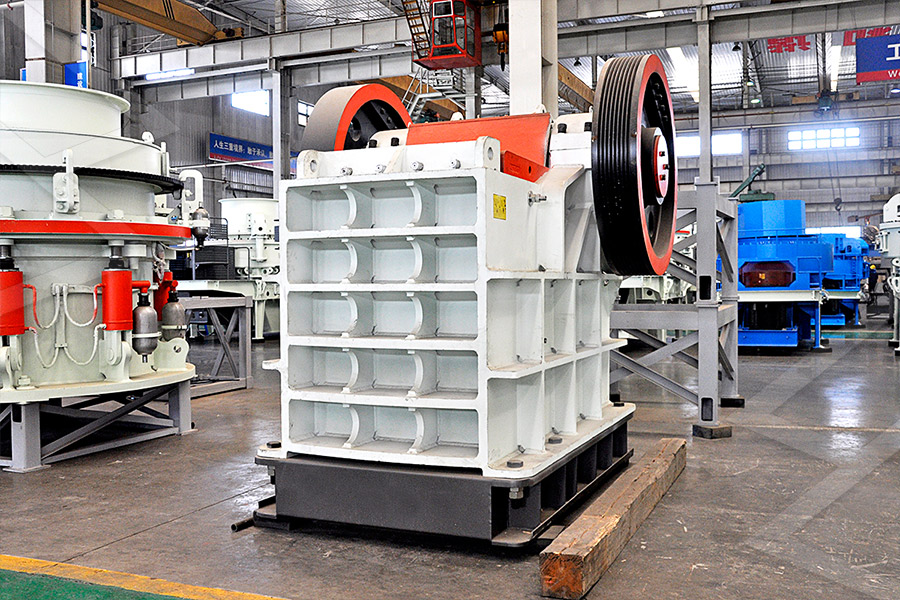

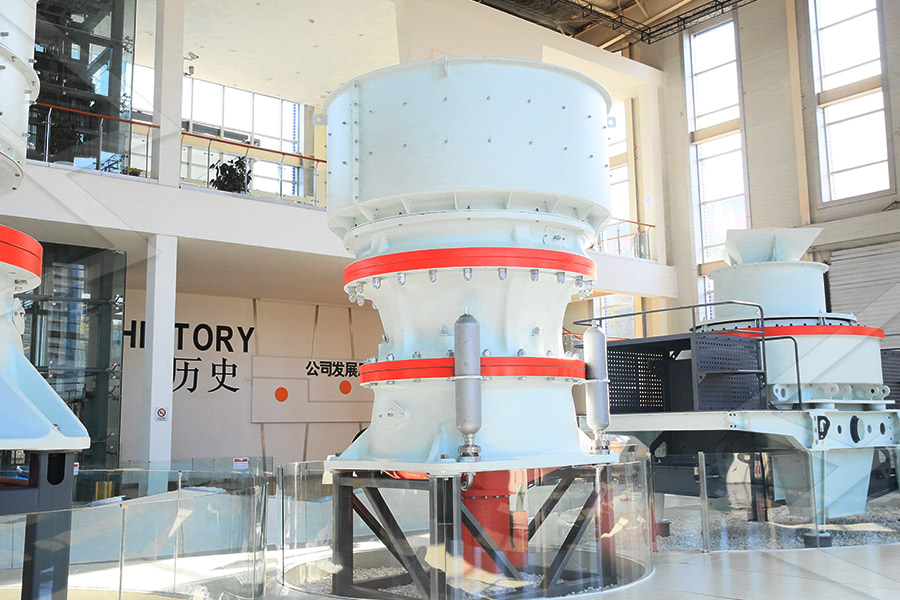

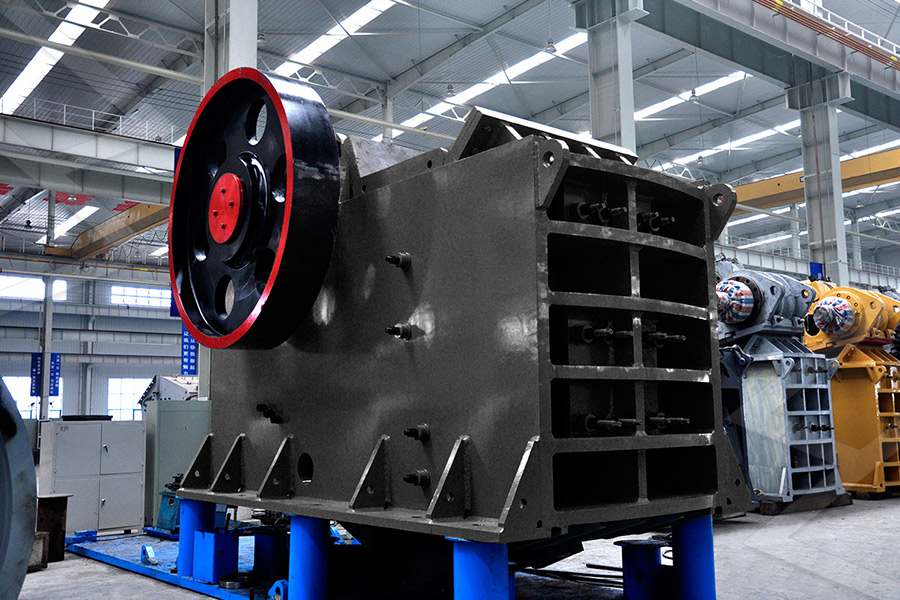

“Computer Aided Design of Jaw crusher” 911 Metallurgist

2024年7月30日 a) Primary crusher – The raw material from mines is processed first in primary crushers The input of such crushers is relatively wider and the output products are coarser in size Example Jaw crusher, Gyratory crusher b) Secondary crusher The crushed rocks from primary crusher are sent to secondary crusher for further size reduction2024年3月1日 Based on the physical dimensions of commonly found transfer chutes [25], a chute was implemented in the numerical modelIn particular, this DEM study used an industrial ore chute with a crosssectional area of 15 × 15 m 2, which commonly transfers around 5000 tons/h [4, 16] as the basis for the investigationsFocus was set on the exit Design principles for wear liners with inserts in mining chutes2021年1月14日 Chute design is a combination of science and art, so it is always wise to consult a conveyor engineer experienced in design systems for specific bulkmaterials handling applications (See Chapter 22: Engineered Flow Chutes for a discussion about advanced chute design ) Transferring the material The primary function of a transfer chuteConventional transFer Chutes fhubspotusercontent20Contribute to dihog/sbm development by creating an account on GitHubsbm/sbm crusher chute designmd at main dihog/sbm

IMPLEMENTATION OF ADVANCED TRANSFER CHUTE

2023年5月9日 downstream conveyor This paper will present the design flow implemented to overcome problems in two case studiese Element Modelling utilising Discret incorporating material characterisation Material testing is relevant in achieving a valid DEM simulation model and subsequently a valuable design tool for transfer chute assessment and design2023年12月6日 Safety is a paramount concern in the design and implementation of laundry chutes These considerations are not just about adhering to regulations; they are integral to ensuring that the chute Laundry Chutes: Engineering a ChuteTRANSFER CHUTES The Transfer Chute Design Manual For Conveyor Belt Systems By C Benjamin, P Donecker, S Huque J Rozentals A Review by Em Prof Peter Arnold and Dr David Hastie, Centre for Bulk Solids and Particulate Technologies Faculty of Engineering, University of Wollongong T here is no doubt that transfer chutes in conveying systems The Transfer Chute Design Manual For Conveyor Belt Systems 2010年6月1日 Transfer chute is widely used in mining processing plants to transfer between belt conveyors from one to another The proper chute design is influence onto belt conveyor run in a stable position The Transfer Chute Design Manual: For Conveyor Belt Systems

.jpg)

Design principles for chutes to handle bulk solidspdf

Design Principles for Chutes to Handle Bulk Solids1 by D Stuart Dick and T A Royal Introduction least minimized, by judicious use of certain chute design principles Chutes are used to direct the flow of bulk solids, eg, from one conveyor belt to another Unfortunately, chutes all too often “fail” to perform reliably7 Transfer Chutes 201 71 Introduction 201 72 Transfer Chute Theory 202 Contents vii 73 General transfer chute design considerations 211 74 Design principles for chutes 211 75 Recommendations on chute design 214 76 Special chute design 215 77 Software availability for chute design 217 78 Installation and maintenance of chutes Tuvalu Principle Of Al Transfer Chute Design2024年1月8日 For transfer chute analysis using CFD, a multiphase simulation is typically used, of which there are two main approaches The first approach is known as the EulerianLagrangianEffective Transfer Chute Design including Dust Control 2024年3月16日 Chute Design Essentials – How to Design and Implement Chutes in Bulk Solids Handling Systems BulkBlog Free download as PDF File (pdf), Text File (txt) or view presentation slides onlineChute Design Essentials How To Design and Implement Chutes

.jpg)

VENUE Transfer Chute Design TUNRA Bulk Solids

2021年12月10日 • Dynamic modelling of transfer chutes • Components for optimum accelerated flow • Optimising transfer chute design for feeding and transfer • Practical implementation of continuum mechanics analysis • Dust control during the transfer and redirection process • Optimising chute geometry for controlled wear in the flow2 天之前 The Transfer Chute Design Manual By C Benjamin, P Donecker, S Huque J Rozentals In today’s conveyor systems the major source of maintenance and maintenance related delays to production The Transfer Chute Design Manual bulkonline1992年9月1日 @misc{etde, title = {Design principles for chutes to handle bulk solids} author = {StuartDick, D, and Royal, T A} abstractNote = {The article discusses the various design principles to be considered in the design of reliable chutes Only the fast (ie accelerated) flow mode in which material flows in contact with the chute bottom and side Design principles for chutes to handle bulk solids (Journal 2021年1月18日 In cases that freefall cannot be avoided, care must be taken in design to properly consider impact angles to efficiently redirect a highspeed stream Commandment #10: The slope of the fines TUNRA’s 10 Commandments for reliable transfer

.jpg)

(PDF) Copyright © 2014 by ASME DESIGN OF A TRANSFER CHUTE

2014年11月18日 The most uncomplicated design for manufacturing incorporated an impact plate, and a straight chute has been selected as the best solution The study also involved identifying areas of the new 2019年10月22日 Rational Design of Conveyor Chutes Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses issues with conveyor chute design identified from commissioning reports Chute detailers often lack understanding of material flow properties and principles of chute design Tests should be conducted to Rational Design of Conveyor Chutes PDF Flow This paper presents a design, and a design method, sufficient to engineer a passive solution to the problem of discharge bias resulting from tonnage fluctuation with soft loading transfer chutes This is achieved by considering the momentum change inherent in the bulk material stream through the hood section of a soft loading transfer pointTransferChuteforBulkMaterialpdfPDF On Sep 1, 2021, Jie Wang and others published Design of Improving Coal Chute in Thermal Power Plant Based on DEM Simulation Technology Find, read and cite all the research you need on (PDF) Design of Improving Coal Chute in Thermal Power

.jpg)

Design of Slewing and Luffing Stacker Transfer Chute

2021年12月10日 Principles of transfer chute design developed by TBS over the course of over 40 years were applied The most favourable design, under the imposed structural constraints, was selected and put forward to the client Following successful commissioning, an in depth study of flow through the transfer was performed, applying continuum 2018年10月23日 Conveyor belts discharge ore into chutes for transport to subsequent processing stages Chutes are designed to guide the ore smoothly onto conveyor belts while containing it and minimizing dust Key design objectives include breaking the velocity of falling ore to reduce wear Pilot plants can be used to test chute designs on actual ore Chutes Design PDF PDF Belt (Mechanical) Structural Steel2015年10月18日 Copper, iron and other hard rock mineral ores utilize the rock box principle to control the flow of primary crushed ore in the transfer chute, typically 200 mm open side settingOn the Design and Analysis of Transfer Chute Systems2020年9月29日 TRASH, LINEN RECYCLING CHUTE INSTALLATION MANUAL CHUTES International Manufacturing 33 Industrial Park Drive Waldorf, MD 20602 18008824883 chutes info@chutes CHUTES International Manufacturing – Page 2 8/8/14 Gravity Flow Trash, Linen Recycling ChutesTRASH, LINEN RECYCLING CHUTE INSTALLATION

Chute Design Essentials How to design and implement

2022年4月28日 7hfkqlfdo 3dshu $xjxvw kxwh 'hvljq (vvhqwldov +rz wr ghvljq dqg lpsohphqw fkxwhv lq exon vrolgv kdqgolqj v\vwhpv $xwkruv $gl )ulwhood2024年5月23日 more uniform feed distribution Following this, the optimal design is implemented during the construction and installation phases to seamlessly integrate the new protective coating feed chute onto the crusher is initiative is anticipated to enhance the operational eciency of mining activities linked with the crusher at MMG/Kinsevere It isNumerical analysis of a protective coating for mining Modeling and simulation is a tool to explore and increase the understanding of a phenomenon This thesis focuses on developing models of crushers and equipment used in the mining industry4: The feeding chute of the HPGR crusher in gray and the 2021年7月1日 The effect of feed chute design on tertiary cone crusher performance at the Sarcheshmeh copper complex was studied by an inhouse developed DEM software called KMPC DEM © To simulate the overall crushing circuit, the multigeometry procedure by improving the routines of object files importing into the simulation environment was DEMbased design of feed chute to improve performance of cone crushers

.jpg)

Structural deign of Chute(s) Structural engineering general

2004年8月11日 I am looking for some design example / guidance for the structural deign of different types of Chutes in material handling application, for example Crusher discharge chute, Screen discharge chute and other types of small or large chutes2020年7月14日 The objective of this study is to analyse the stress distribution in a transfer chute when it is in use and to validate design is free from plugging The modelling was done using the CREO (PDF) Stress Analysis and Design Validation of Chute2015年5月24日 chute transfer problems, test new chute design concepts, and model different material conditions These abilities have led to new innovations in chute design, including the curved chute or “spoon” geometry When a curved chute design has been fully tested and optimized for all of the conveyed materials using DEMMINIMIZING BELT WEAR AND DAMAGE FROM Chutes are in use in almost every bulk solids handling plant Although everybody knows them, they are mostly overlooked, except for those cases where they cause extraattention and work due to malfunctioning Following you will find hints to prevent such incidents This paper attempts to give the reader some simple rules to apply to chute Chute Design Essentials – How to Design and Implement

.jpg)

StuartDickRoyalDesign Principles For Chutes

2021年7月8日 This document discusses two key design principles for chutes used to handle bulk solids: 1 Chutes must be steep enough to prevent material from adhering or plugging at impact points, such as Transfer chutes are used in bulk handling systems to perform a variety of operations For instance accelerating the bulk material from a slow moving belt or apron feeder onto a conveyor, or capturing and redirecting the Transfer Chute Design TUNRA Bulk Solids2020年4月1日 the chute design with DEM simulations then, as a minimum, a continuum model should be consulted to determine the chute’s minimum slope or cutoff angle The continuum model requires much less design work to be completed and can provide chute cutoff angles for several chute design options in a relatively short timeTransfer Chute Analysis with Discrete Element and 2020年4月1日 Jenike Johanson Design principles for chutes to handle bulk solidspdf Free download as PDF File (pdf), Text File (txt) or read online for free Scribd is the world's largest social reading and publishing siteJenike Johanson Design Principles For Chutes To Handle

Crushing Plant Design and Layout Considerations 911

2016年2月24日 design, so that they can identify ways of reducing overall electrical power consumption • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001)4 天之前 The spiral chute combines the advantages of a spiral concentrator, shaking table, and centrifugal concentrator It is an essential tool for mineral processing and recycling It can effectively extract different minerals based on specific gravity The versatility and adaptability of spiral chutes make them suitable for various mineral processing Improving Mineral Processing Efficiency With Spiral Chutes2024年7月30日 a) Primary crusher – The raw material from mines is processed first in primary crushers The input of such crushers is relatively wider and the output products are coarser in size Example Jaw crusher, Gyratory crusher b) Secondary crusher The crushed rocks from primary crusher are sent to secondary crusher for further size reduction“Computer Aided Design of Jaw crusher” 911 Metallurgist2024年3月1日 Based on the physical dimensions of commonly found transfer chutes [25], a chute was implemented in the numerical modelIn particular, this DEM study used an industrial ore chute with a crosssectional area of 15 × 15 m 2, which commonly transfers around 5000 tons/h [4, 16] as the basis for the investigationsFocus was set on the exit Design principles for wear liners with inserts in mining chutes

.jpg)

Conventional transFer Chutes fhubspotusercontent20

2021年1月14日 Chute design is a combination of science and art, so it is always wise to consult a conveyor engineer experienced in design systems for specific bulkmaterials handling applications (See Chapter 22: Engineered Flow Chutes for a discussion about advanced chute design ) Transferring the material The primary function of a transfer chute