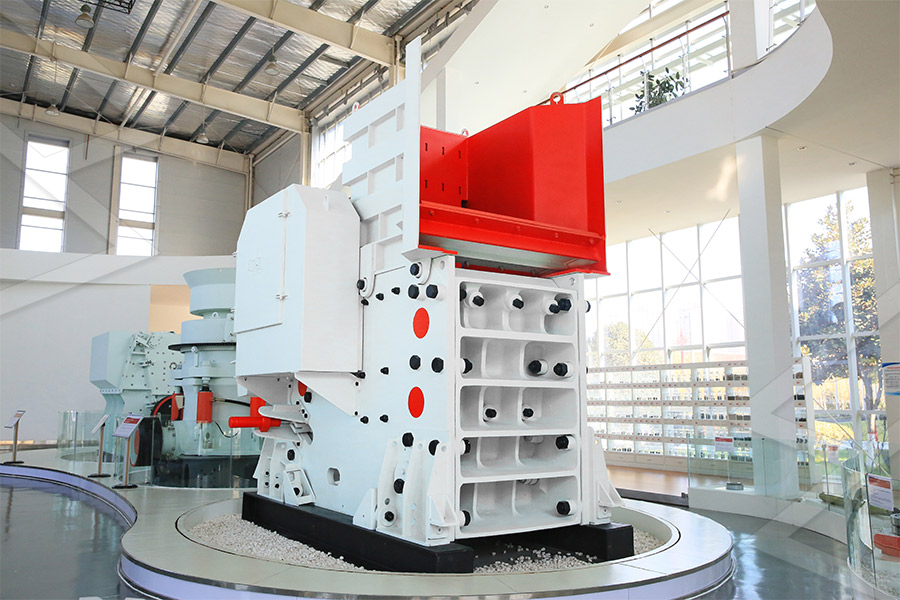

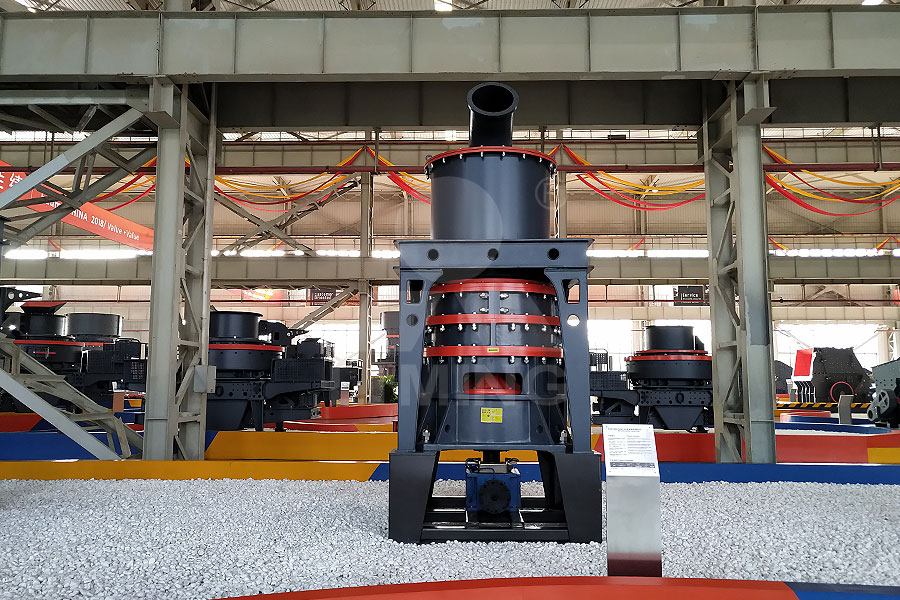

Fine Particle Grinder

.jpg)

Fine Grinders, Hammer Mills, and More for

Designed to grind dry, freeflowing material down to 200 mesh with very tight particle distribution, our fine grinders are also ideal for heatsensitive materials such as powder coatings, sugars, and resinsBühler's Pulverex 5 Series hammer mill provides industryleading throughputs for fine grinding applications, on a wide range of products, and with an exceptionally uniform particle size distributionPulverex™ 5 Series pulverizer Bühler Group2022年8月30日 The Supermasscolloider ultrafine grinders feature two ceramic nonporous grinders (patented in 12 countries), which are adjustable at any clearance between the upper and lower grinder Using ceramic Ultrafine friction grinder "Supermasscolloider"2020年11月9日 立式磨是利用磨辊与磨盘的相对运动对物料进行料床粉碎,作为非金属矿粉体干法超细加工技术的主要进展之一,立式磨装备与技术在非金属矿产业规模化和产品精细化实践应用中,渐渐突现出高效、节 非金属矿行业常用11大类粉磨设备 破碎与粉磨专栏

.jpg)

Fine grinding by granulators and pulverizers

Our SMF fine granulators and PU impact disc pulverizers have been developed for use in the fine grinding of plastic granulates and waste, and other soft to mediumhard materials The final particle sizes to be 2021年3月2日 生料立式磨 粉磨效率高。 采用先进的料层粉磨原理,使系统电耗比球磨机节能20~30%,随原料水分增加,节电效果更为显著; 烘干能力大。 可利用窑热风废气烘 粉磨设备产品中心江苏鹏飞集团股份有限公司2017年2月17日 This article evaluates the effects of operating parameters on fine particle grinding process with a vertically stirred media mill The effects are investigated through Effect of operating parameters on fine particle grinding in a 2020年9月20日 For instance, approaches like the Discrete Element Method (DEM) are very promising options However, due to the high computing capacity, which is required for simulating high numbers of fine particles, this method is still under development in terms of simulating the particle behavior within industrial dry fine grinding processes 22Grinding aids for dry fine grinding processes ScienceDirect

.jpg)

Evolution of grinding energy and particle size during dry ball

2020年10月1日 It evolves during the grinding process with an increasing cohesive stress, defined as the additional stress induced by cohesive forces between particles, as the average particle diameter is reduced Hence, for finemilling, both interparticle and intraparticle surface energies are to be overcome for grinding the material [2] In all cases 18 小时之前 Highspeed grinders tend to produce a wider PSD, with more fines (ultrafine particles) that can lead to overextraction By reducing the grinder speed, the particle size distribution becomes narrower, resulting in more uniform grounds This leads to a more balanced extraction and reduces the risk of bitterness or astringency in the final cup 3Variable Speed Grinders and Their Impact on Grind Quality2017年1月10日 This paper evaluates the effects of operating parameters on fine particle grinding process with a vertically stirred media mill The effects are investigated through size reduction under different Effect of operating parameters on fine particle grinding in a 2023年9月9日 Say you want to confirm particle size at a grinder setting of 12 This tool will help you make that distinction, in a very precise way Even though your grinder might say 12 is “mediumfine,” the particle size measurement may prove otherwise The Encore is most uniform and precise when set in the 1028 rangeBaratza Encore Grinder Settings: the Perfect Grind Size

.jpg)

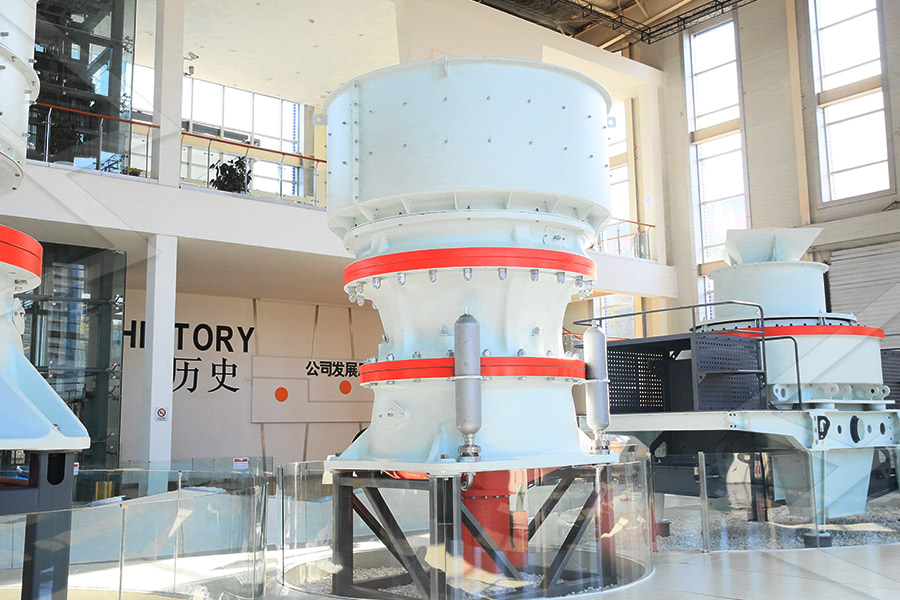

Energy Use of Fine Grinding in Mineral Processing

2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s 2016年4月18日 Furthermore, we elucidate the influence of bean temperature on particle size distribution, concluding that grinding cold results in a narrower particle size distribution, and reduced mean particle The effect of bean origin and temperature on grinding Prater Fine Grinders (M Series Mills) are designed to grind dry, freeflowing material as fine as 400 mesh (37 microns) with a very tight distribution of particle size The highly efficient design allows for ease of access to all internals and is well suited for heatsensitive materials such as resins and sugarM Series Fine Ginder Commercial Dry Grinder Prater 2018年6月1日 In fine grinding, energy consumption and wood powder properties are closely related to the particle size of the product The energy consumption of fine grinding increases exponentially with decreasing particle size The aspect ratio and crystallinity decrease as the particle size decreases while the specific surface area increasesFine grinding of wood – Overview from wood breakage to

.jpg)

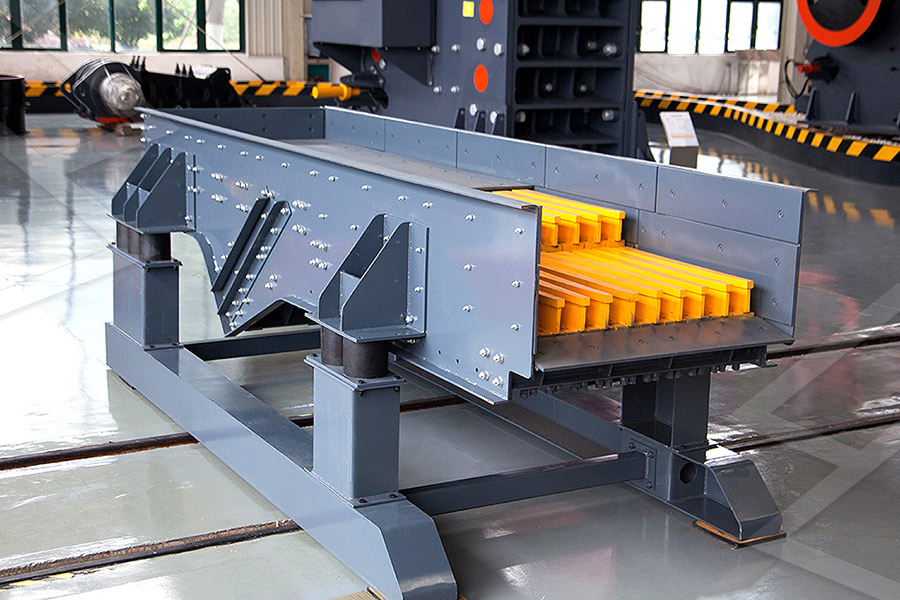

Fine Grinding Machines and Micronizing Equipment Bepex

Fine grinding lies at the heart of many processing applications, either as an intermediate step in processing or to produce a final, salable product Agglomeration, a process integral to various industries, involves the consolidation of fine particles into larger, cohesive structures to enhance product performance and handling 2023年10月9日 The final theory of particle reduction is Bond’s Law that states the total work input by the weight of crushed material is inversely proportional to the square root of the diameter of the product particles (Figure 7) Bond’s Law functions best in between the coarse grinding of Bond’s Law and the fine grinding of Rittinger’s Law E √ Principles of Sample Preparation by Grinding or The grinding action is created by a variable speed stirrer which agitates the grinding media The feed particles pass through the media bed entrained in the airstream and exit into an air classifier where the on size particles are Fine grinding mills2023年3月29日 Our ultrafinegrinding system uses the cooling power of liquid nitrogen to remove heat produced in the grinding process by controlling the temperature of your product or the mill Key benefits include the following: • Ultrafine particle size • More uniform particle distribution • Higher yields of particles in your target rangePolarFit™ UltraFineGrinding Mill Air Products

.jpg)

Mastering the Art of Grinding Fine Powder: Tips and

2024年5月11日 The process of grinding aims to reduce the particle size of materials to create a fine powder with consistent particle size distribution This is vital for achieving uniformity in products such as pharmaceutical drugs, food ingredients, pigments, and cosmetics, where precise particle size control is critical for performance and appearance2022年1月29日 Uneven, nonuniform grounds are a big problem since it’s not possible to adjust the brewing process to account for both the fine particles and the large particles 2 Grounds Too Large If your coffee grinder slackens off over time, eventually you will notice the particle size getting larger and largerHow to Calibrate and Adjust Your Coffee Grinder Not Not In fact, manual grinders can even outperform electric grinders when it comes to extremely fine grinding Another benefit to a manual grinder is most of them are portable and easy to pack on a trip By buying a manual grinder it allows you to take your equipment wherever you go and is an asset if you travel a lot and want to try fresh coffee all Complete Burr Grinder Guide Coffee Informer2024年3月19日 From the extra coarse grinds used in French press brewing to the ultrafine particles required for espresso, each grind size has its unique purpose and impact on the final cup You can also run some white rice through the grinder to help dislodge stubborn particles Cleaning a Burr Grinder Burr grinders require more thorough cleaning The Ultimate Guide to Different Coffee Grind Sizes

.jpg)

Producing Fine Particles for Multiple Applications AZoM

For example, ultrafine particles can be separated out by adjusting the grinding clearance to the narrowest setting This improves the overall efficiency of the grinding system Processors are increasingly choosing to test alternative technologies before making a capital investment and selecting a new grinding systemThe addition of RPM as a variable can significantly affect the particlesize distribution of the grounds produced, with higher RPMs generally increasing the fraction of fine particles for a given grinder setting Comparing particlesize distributions at different RPMs can help identify the best speed for your grinderCoffee Grind Lab – Coffee particle size distributions Bühler's Pulverex 5 Series hammer mill provides industryleading throughputs for fine grinding applications, on a wide range of products, and with an exceptionally uniform particle size distribution leading throughputs for fine grinding applications, on a wide range of products, and with an exceptionally uniform particle size Pulverex™ 5 Series pulverizer Bühler Group2017年8月31日 These strands crisscross to form void spaces, or "cells" Researchers estimate a typical bean contains a million such cells Roasting makes the cellulose brittle and grinding shatters the cellulose structure Fines: Fine for Espresso, Not So Fine For Filter

Fine grind pharmaceutical powders to gain

2020年7月30日 The F10 is the only fine grinding technology that provides operators with four separate variables with which to adjust and finetune the particle size distributions and capacities By simple adjustments to 2023年11月17日 The Encore won't get you immaculate grounds, but it will reduce the number of boulders and fines (how coffee pros refer to toolarge and toosmall particles) in each grind Using Kruve sieves The 6 Best Coffee Grinders in 2023, Tested and 2023年6月16日 The size of the coffee particles in a dose of grounds is one the most important factors in determining the taste of a cup of coffee Measuring the distribution of those particle sizes is essential for knowing how effective and consistent coffee grinders are Coffee particle size distribution refers to the mix of coarse and fine particle Measuring Grind Size Distribution: Three Methods Craft 2020年6月13日 Laser diffraction particle size analysis performed by our friends at Horiba Instruments confirmed that of the four grinders we tested for this report, the Smart Grinder Pro, at a variety of settings, generates the highest percentage of grounds within an optimal range of particle size Its best performance was at a fine grind of a light roast Coffee Grinder Review: Breville Smart Grinder Pro at

.jpg)

(PDF) A Review on Cryogenic Grinding ResearchGate

2020年7月24日 Cryogenic shredding is able to produce a fine particle size at very low temperature using liquid nitrogen, thus, preventing such unwanted processes (Junghare et al, 2017) Robinson et al (2016 2009年3月1日 Attention will turn now to the published evidence of how fine particle floatability may be affected by the grinding environment In a study on a lead/zinc ore at laboratory scale, grinding with high chromium alloy steel media increased fine (−5 μm) galena maximum recovery compared with grinding with high carbon steel (mild steel) The critical importance of the grinding environment on fine particle 2023年12月6日 This is because of the grinder’s excellent particle size distribution within this range The Encore excels at brew methods ranging from moka pot to pourover drippers to French press! Turkish Coffee requires superfine particles of 100200um, and the Encore’s burr just does not grind fine enough You can try going as fine as your Baratza Encore Grind Settings: Our Helpful Indepth GuideThe ball mill is a traditional equipment for ultrafine grinding, and the product particle size can reach 2040 microns When the product particle size is required to be below 20 microns, the efficiency is low, the energy consumption is large, and the processing time is long Stirring mill is developed on the basis of ball mill, which is mainly What is the purpose of fine grinding? lkmixer

.jpg)

Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian

2023年8月28日 The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine 1 天前 Pulse grinding helps maintain control over the grind size and prevents overheating the coffee grounds, which can affect flavor It is particularly useful for achieving a consistent grind and avoiding fines or #1 and ultimate guide to grinding of coffee4 天之前 Technique Finenesses from d 97 10 µm to d 97 250 µm (based on limestone); Air classifier with vertical shaft; Vortex free fines outlet with expansion chamber to reduce circumferential speed and wear as well as CFS Fine Classifier NETZSCH GrindingABSTRACT This article evaluates the effects of operating parameters on fine particle grinding process with a vertically stirred media mill The effects are investigated through size reduction under different operating conditions by changing solids content, tip speed and the configuration of the impeller Solids content at 65% (w/w) is demonstrated to be more Effect of operating parameters on fine particle grinding in a

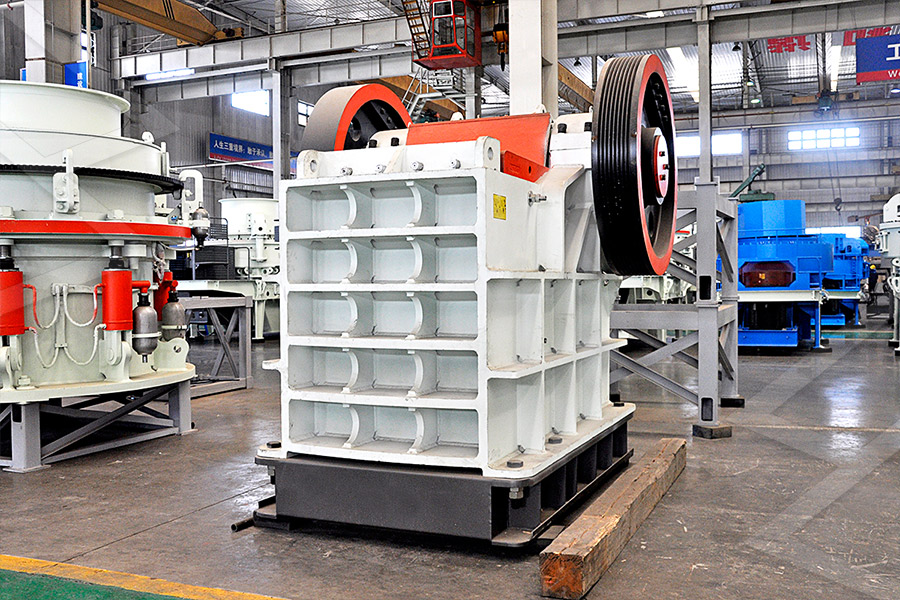

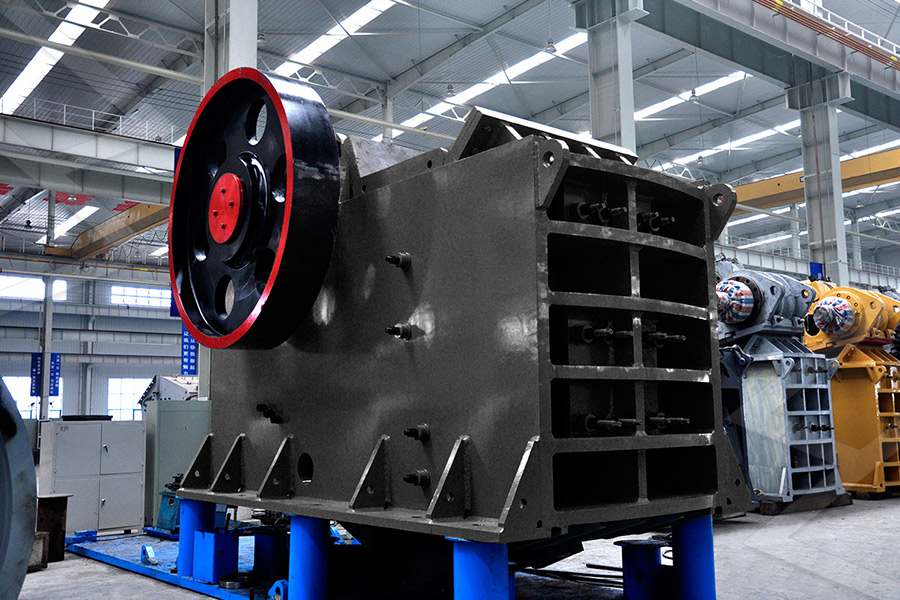

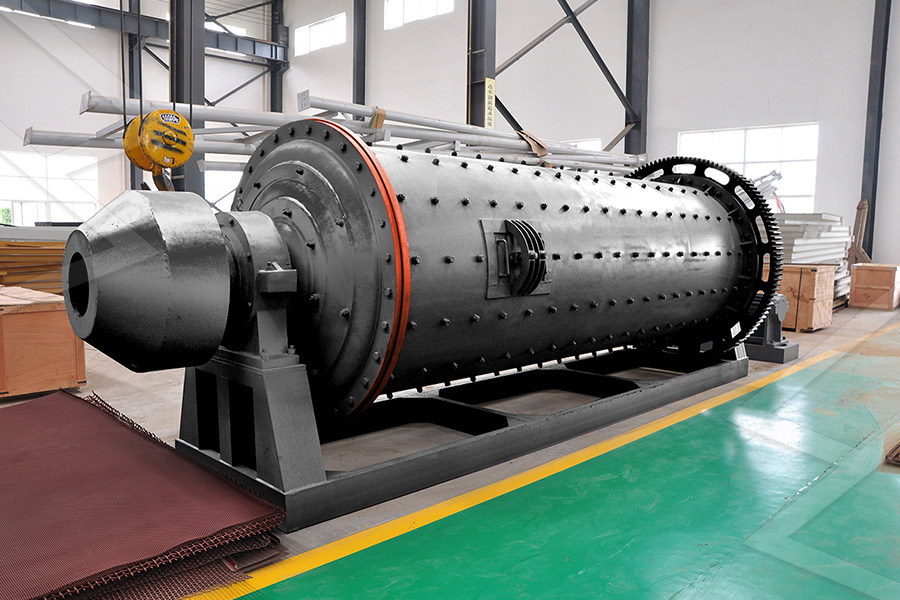

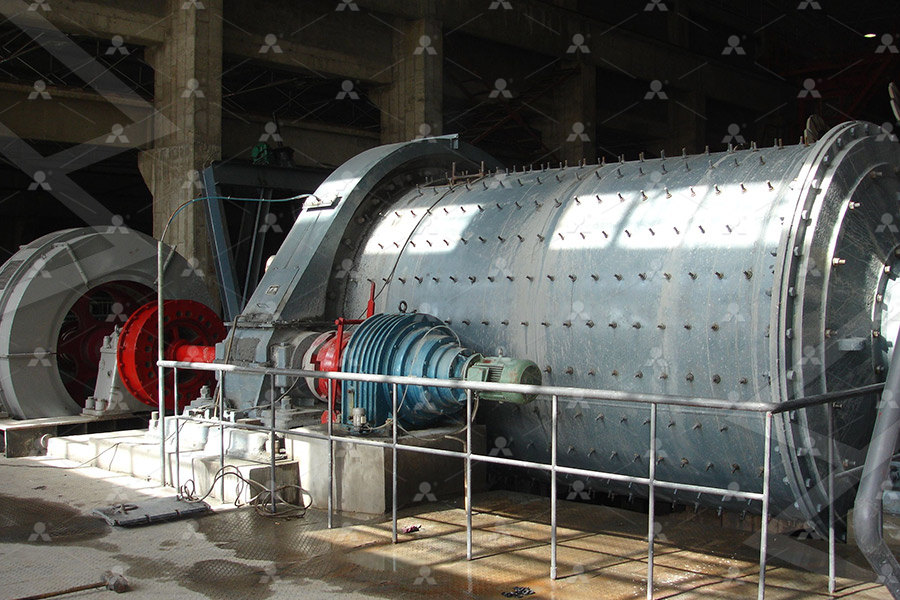

Ore Grinding SpringerLink

2023年7月20日 In the mineral processing industry, ore grinding is the particle size preparation before the separation of the crushed ore Except those that process some placers, almost all mineral processing plants have grinding operations, in which materials are crushed by the impact and abrasive action of grinding medium (steel rod, steel ball, 2019年5月14日 A medium to mediumfine grind size — 375800 microns — allows for a steady flow of water through the coffee bed, preventing excessive clogging, slow filtration, or fine particles from entering the lower chamber V60 400700 microns The V60 is a popular pourover coffee brewing device that was created by the Japanese company HarioCoffee grind size chart Honest Coffee GuideAlso, a noisy grinder indicates that the motor is running quickly Speed is pivotal but if the grinder runs too much it could break Because of this, examine the grinder’s decibel levels If you prefer a quiet grinder, make sure it uses less than 50 decibels In most cases, cone grinders tend to be a bit quieter than burr ones Grind DistributionFlat vs Conical Burr Grinders: What’s Really the Difference?2023年11月7日 Steel balls as traditional grinding media are prone to excessive fines generation and high energy consumption Therefore, in light of this problem, the authors investigated another media—ceramic balls based on the output characteristics of fine particles This study discusses the effect of ceramic balls on the change of the particle Effect on Fine Particles Output Characteristics of Ceramic Ball Grinding

Metallographic grinding and polishing insight Struers

When plane grinding, abrasive particles can become embedded in soft materials Continue with a somewhat finer grit surface (ie MD/DPPan with DiaPro Pan 15 um) as a second plane grinding step and MDLargo for fine grinding Fine grinding produces a surface with little deformation that can easily be removed during polishing Because of the 2010年5月15日 In this work the stability of ground organic particles has been studied Laser diffraction measurement showed that the particle size after grinding was in the submicron range Dynamic light scattering measurements, on the other hand, showed that there were larger particles present after grindingStability of particle suspensions after fine grinding2024年4月20日 Fine grinders: Fine grinders, as the name suggests, are designed for fine grinding of rubber particles These machines use highspeed rotors or centrifugal force to pulverize the rubber into a fine powder Fine grinders are commonly used in industries that require ultrafine rubber particles for applications such as rubber modified asphalt The Ultimate Guide To Choosing The Right Rubber Grinder 2020年9月20日 For instance, approaches like the Discrete Element Method (DEM) are very promising options However, due to the high computing capacity, which is required for simulating high numbers of fine particles, this method is still under development in terms of simulating the particle behavior within industrial dry fine grinding processes 22Grinding aids for dry fine grinding processes ScienceDirect

.jpg)

Evolution of grinding energy and particle size during dry ball

2020年10月1日 It evolves during the grinding process with an increasing cohesive stress, defined as the additional stress induced by cohesive forces between particles, as the average particle diameter is reduced Hence, for finemilling, both interparticle and intraparticle surface energies are to be overcome for grinding the material [2] In all cases 18 小时之前 Highspeed grinders tend to produce a wider PSD, with more fines (ultrafine particles) that can lead to overextraction By reducing the grinder speed, the particle size distribution becomes narrower, resulting in more uniform grounds This leads to a more balanced extraction and reduces the risk of bitterness or astringency in the final cup 3Variable Speed Grinders and Their Impact on Grind Quality2017年1月10日 This paper evaluates the effects of operating parameters on fine particle grinding process with a vertically stirred media mill The effects are investigated through size reduction under different Effect of operating parameters on fine particle grinding in a 2023年9月9日 Say you want to confirm particle size at a grinder setting of 12 This tool will help you make that distinction, in a very precise way Even though your grinder might say 12 is “mediumfine,” the particle size measurement may prove otherwise The Encore is most uniform and precise when set in the 1028 rangeBaratza Encore Grinder Settings: the Perfect Grind Size

.jpg)

Energy Use of Fine Grinding in Mineral Processing

2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s 2016年4月18日 Furthermore, we elucidate the influence of bean temperature on particle size distribution, concluding that grinding cold results in a narrower particle size distribution, and reduced mean particle The effect of bean origin and temperature on grinding Prater Fine Grinders (M Series Mills) are designed to grind dry, freeflowing material as fine as 400 mesh (37 microns) with a very tight distribution of particle size The highly efficient design allows for ease of access to all internals and is well suited for heatsensitive materials such as resins and sugarM Series Fine Ginder Commercial Dry Grinder Prater 2018年6月1日 In fine grinding, energy consumption and wood powder properties are closely related to the particle size of the product The energy consumption of fine grinding increases exponentially with decreasing particle size The aspect ratio and crystallinity decrease as the particle size decreases while the specific surface area increasesFine grinding of wood – Overview from wood breakage to

.jpg)

Fine Grinding Machines and Micronizing Equipment Bepex

Fine grinding lies at the heart of many processing applications, either as an intermediate step in processing or to produce a final, salable product Agglomeration, a process integral to various industries, involves the consolidation of fine particles into larger, cohesive structures to enhance product performance and handling